Description

Description:

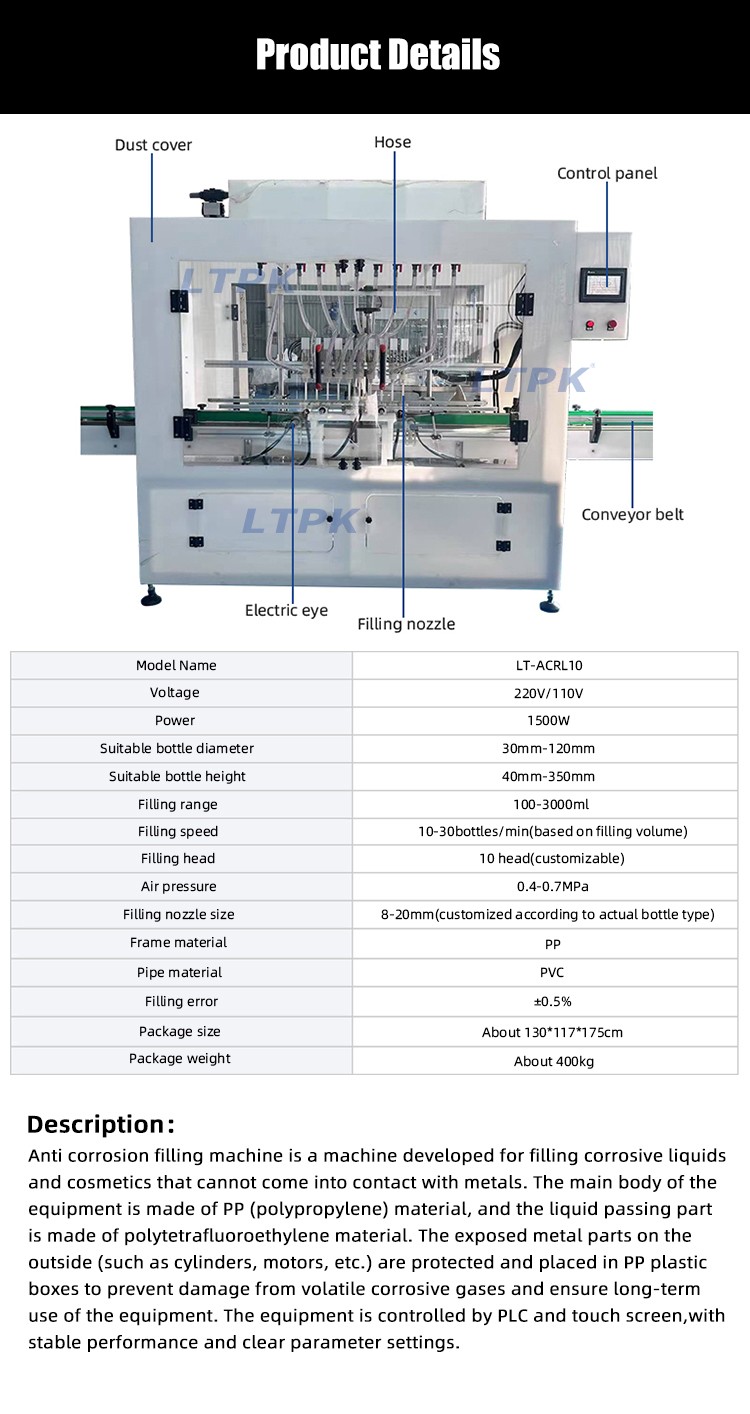

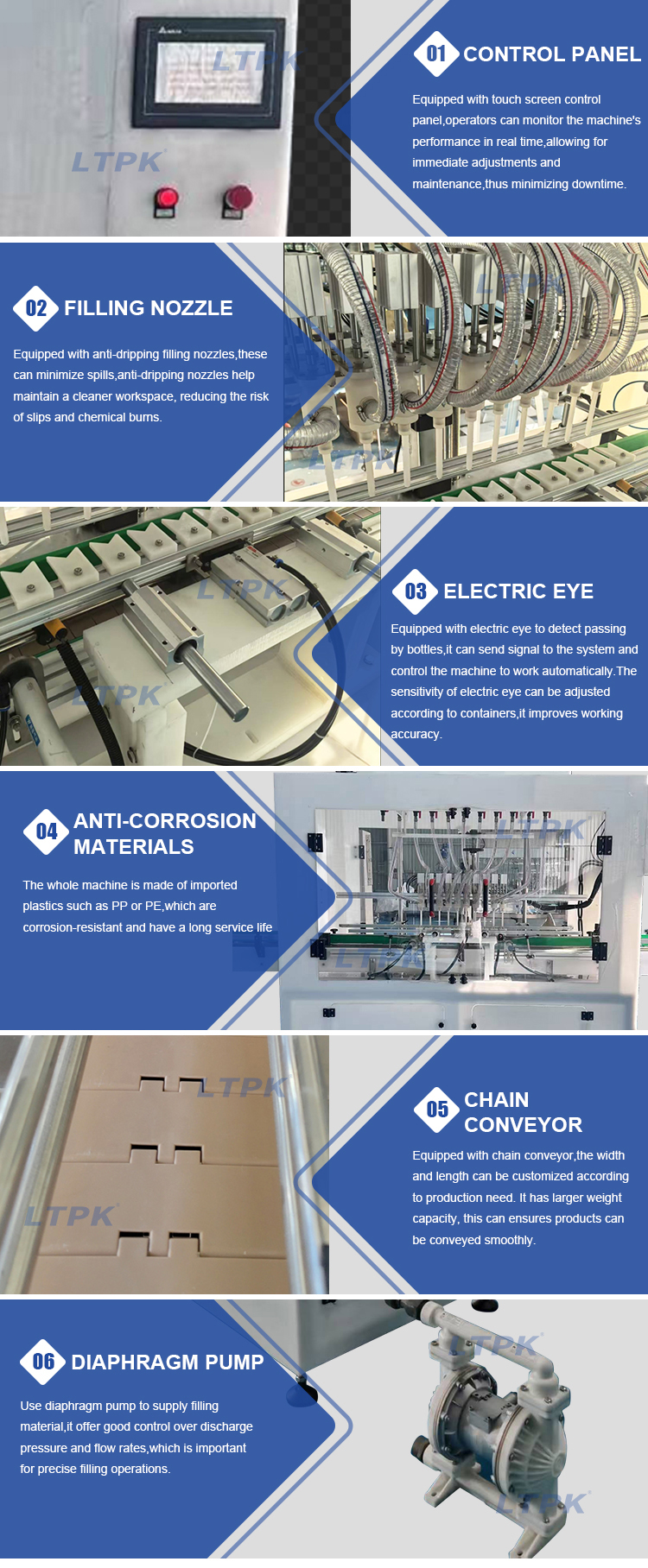

Anti corrosion filling machine is a machine developed for filling corrosive liquids and cosmetics that cannot come into contact with metals. The main body of the equipment is made of PP (polypropylene) material, and the liquid passing part is made of polytetrafluoroethylene material. The exposed metal parts on the outside (such as cylinders, motors, etc.) are protected and placed in PP plastic boxes to prevent damage from volatile corrosive gases and ensure long-term use of the equipment. The equipment is controlled by PLC and touch screen,with stable performance and clear parameter settings.

Application:

Suitable for Pesticides, herbicides, insecticides, fungicides, seed coating agents, insecticides, foliar fertilizers, liquid fertilizers, 84 disinfectant, toilet cleaner, iodine, hydrochloric acid, sulfuric acid and other corrosive liquids.

Technical parameters:

Model | LT-ACRL10 |

Voltage | 220/110V |

Power | 1500W |

Suitable bottle diameter | 30mm-120mm |

Suitable bottle height | 40mm-350mm |

Filling range | 100-3000ml |

Filling speed | 10-30bottles/min(based on filling volume) |

Filling head | 10 head(customizable) |

Air pressure | 0.4-0.7MPa |

Filling nozzle size | 8-20mm(customized according to actual bottle type) |

Frame material | PP |

Pipe material | PVC |

Filling error | ±0.5% |

Package size | About 130*117*175cm |

Package weight | About 400kg |