Description

Description

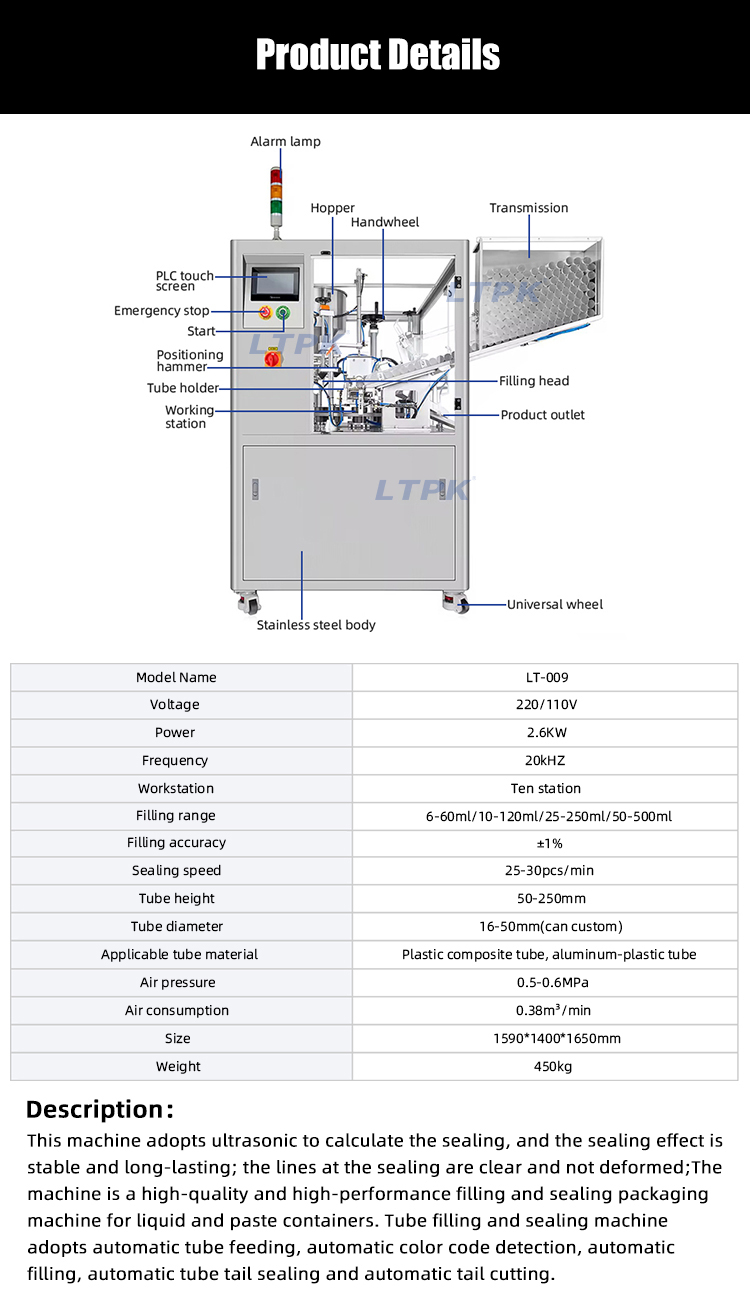

Introducing our new automatic tube filling and sealing machine! Equipped with a tube loading station and pick and place station, the machine efficiently transfers tubes to the tube orient station where color-coded identification ensures accurate positioning. The filling station features a piston pump and material hopper, while the sealing station uses ultrasonic technology to cut and code each tube with a unique production date. Then the pneumatic trim station is where the top of the tube is trimmed to create a clean and professional finish. Finally, the unload station releases finished tubes from the star wheel. Save time and increase productivity with our reliable and user-friendly machine.

Technical Parameters

Model LT-009

Voltage 220V/110V, 50/60Hz

Power 2.6kW

Hopper Capacity 30L

Filling Range 6-60ml/10-120ml/25-250ml

Filling Accuracy ±1%

Capacity 18-28pcs/min

Tube Diameter 16-50mm

Tube Height 70-210mm

Cutting Method Ultrasonic, 20kHz

Air Pressure 0.6Mpa

Application Aluminum-plastic soft tube,plastic soft tube

Machine Material Stainless

Steel

Net Weight/Gross Weight About 450kg/555kg

Machine Size About 1615*1400*1590mm

Package Size About 1610*1760*1860mm